(August 26, 2023) The triumph of India’s lunar mission, Chandrayaan-3, is not only a cause for celebration within the nation but is also gaining global recognition. Amidst the accolades rightfully directed at our scientists, there exists a group of individuals who have been diligently toiling in the background, playing a crucial role in the accomplishment of this monumental mission. Among these unsung heroes stands the Bandaru family from Hyderabad, and at the heart of their efforts lies their company, CNC Technics.

Vijay Krishna Bandaru with his sons Rahul and Rohit

Established by Vijay Krishna Bandaru in 1987, this firm has been working silently yet significantly, contributing to India’s remarkable advancements in aerospace and space exploration. In close collaboration with the Indian Space Research Organisation (ISRO), CNC Technics has proven to be an indispensable partner, utilising its advanced manufacturing capabilities to drive the success of ISRO’s endeavours. Currently managed by his sons, Rahul and Rohit Bandaru, the company’s directors, CNC Technics has been a significant part of various ISRO missions.

“We developed the cryogenic fuel lines, which are instrumental in transporting fuel from storage tanks to the combustion area, for the Vikram Sarabhai Space Centre (VSSC), which were used in the third stage (cryogenic stage) of the launch vehicles to transport the two fuels from the storage tanks to the combustion area,” shares Rahul as he connects with Global Indian, adding, “It has been a great privilege to be a part of India’s space odyssey. We are very happy to be able to contribute to this magnificent journey.”

CNC Technics

It’s not just ISRO, this company has forged partnerships with prominent names like SpaceX and Taiwan Aerospace on the international stage. Their offerings extend to supplying equipment to subcontractors and suppliers for SpaceX, NASA, and the European Space Agency. What’s more, they are working hard on equipping local space agencies and nurturing innovation on a worldwide scale.

Standing along ISRO

This story starts when India successfully tested five nuclear bombs at Pokhran. The tests subsequently resulted in various foreign economic sanctions being imposed on the country, banning the export of certain defense materials and technologies. However, what seemed like a tragedy, turned out to be a great opportunity for the country to start making these projects at home. And Vijay Bandaru grabbed this opportunity with both hands. His company made its mark early on by developing the first CNC Filament Winding Machine in India back in 2000, an achievement inaugurated by the late Dr. Abdul Kalam during his tenure as the Scientific Advisor.

“My father is an IIT Madras graduate and has been a part of ACC Cement at the start of his career. In fact, he was the man behind the introduction of Ceasefire Fire Extinguisher to the market,” says Rahul. “Our partnership with ISRO started in 2008, and we have been a part of various missions The journey of creating intricate components for ISRO has been a mix of years of research and development in various engineering spheres, including material engineering, processing, molding, robotics, and process engineering.”

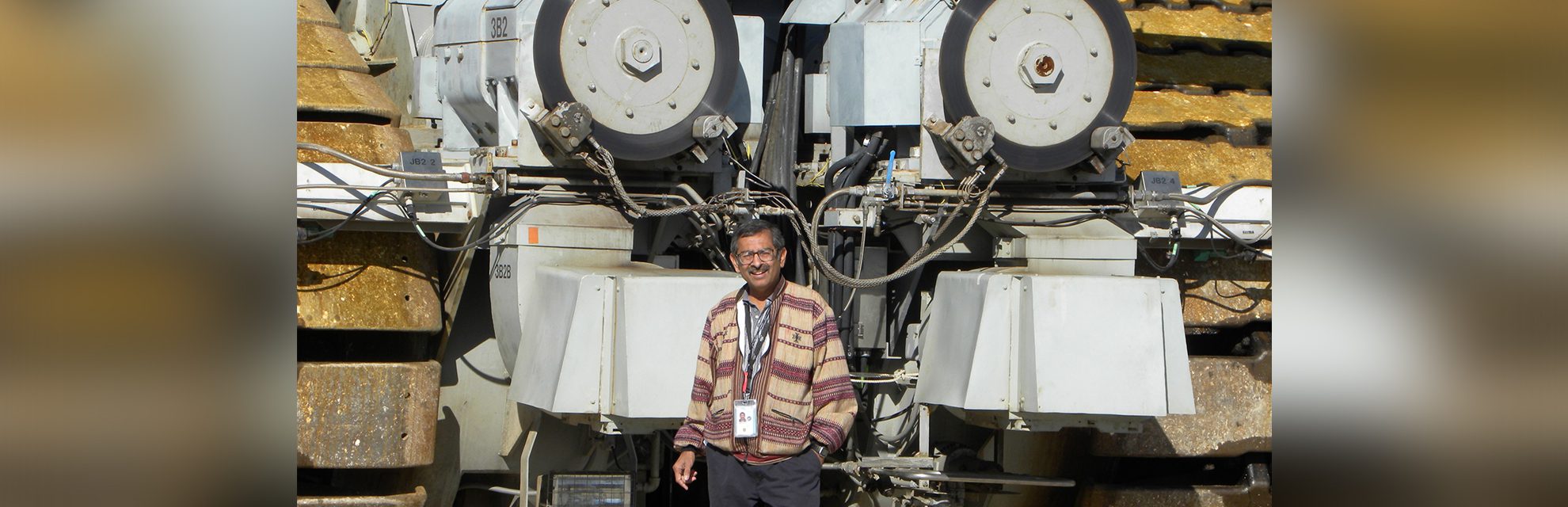

CNC Technics’ 6 Axes 1 Spindle winder

Shedding light on their collaboration with ISRO, he says, “There are three stages to launch a space satellite. While the first two stages were made in India, until a few years ago, ISRO would export the third stage – cryogenic stage – was being bought from Russia. ISRO reverse-engineered a way to manufacture the cryogenic stages in India, and they approached us to make the cryogenic fuel lines for that purpose. We worked with them for about seven years to produce these pipelines which were then used in the subsequent flights.”

CNC Technics played a very vital role in the historic launch of 104 satellites at the Satish Dhawan Space Centre (SDSC). “Since then, we have been at the forefront of manufacturing critical components for the aerospace industry, aligning seamlessly with ISRO’s goals.” In 23 years, CNC Technics has crafted over 280 machines, extending their reach to more than 30 nations, encompassing the UK, USA, Russia, Canada, and Australia.

Adventurous duo

If you were thinking that with so many projects on their hands, Rahul’s and Rohit’s lives would only be about work, you couldn’t be more wrong. The duo, who is quite invested in developing new technology for the country, are also quite adventurous. “I am quite a fitness freak,” laughs Rohit, “I recently did a 5k swimathon in Goa. I also have a Half Ironman Triathlon under my belt, and now training for a full Ironman too.” And he isn’t just done as yet. Rohit is also an avid hiker and mountaineer, who has scaled several peaks across the globe. “The trick is to plan in advance,” he says talking about how he manages to find time for these activities, “I mostly have a whole year scheduled and I make sure that all the work is done before I take the vacations.”

Rohit Bandaru is a fitness enthusiast

Rahul, who is a self-proclaimed “food lover”, holds a special place for motorbiking in his heart. “I also swim. But, in all honesty, I am a father of a small kid so currently all my time is just dedicated to home,” he shares.

The future looks promising

Beyond its contributions to aerospace, CNC Technics lives by its core values of pioneering innovation. Their brand, Helipole has introduced revolutionary composite lighting solutions – completely non-metallic street light poles that outlast traditional alternatives while ensuring safety and durability. Additionally, the company is working on the next generation of carbon fiber pressure vessels, aiming to replace steel gas cylinders for greener hydrogen and CNG fuels. “Our goal is to remain at the forefront of innovation in this industry, introducing novel products to the Indian ecosystem that are yet to make their mark in the local market,” shares Rahul.

Currently, CNC is heavily investing in ISRO’s first crewed orbital spacecraft – Gaganyaan. “We have already started working on developing larger fuel lines for Gaganyaan. I must add that ISRO’s professionalism and their intensity is very commendable and keeps us inspired,” shares Rahul, as he signs off.

- Follow CNC Technics on their website